.png?width=1640&height=645&name=Group%2078%20(1).png)

NET@PRO

APS, MRP and

DDMPRP

APS, MRP and DDMPRP

What are they?

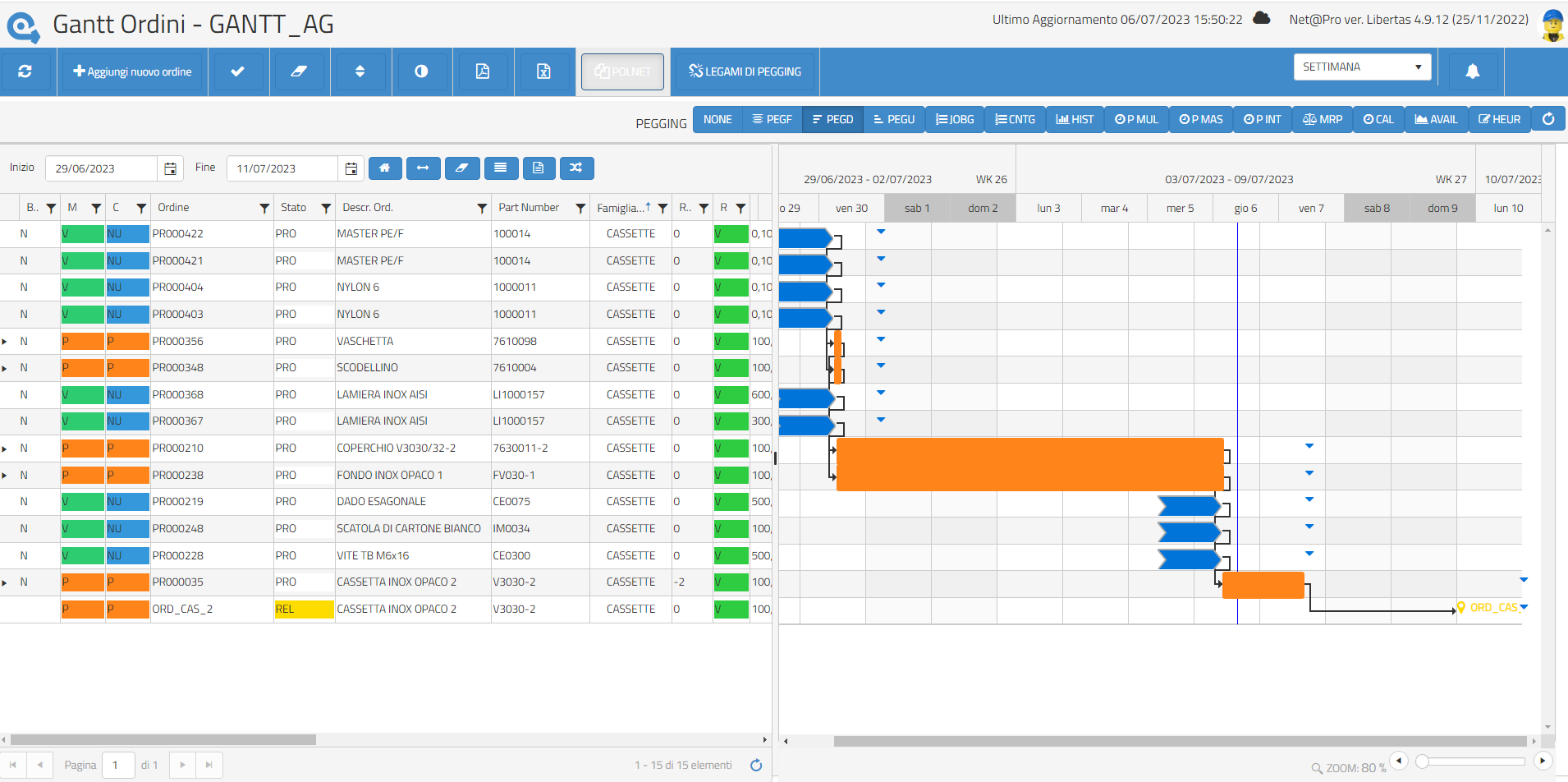

APS -> Advanced Planning & Scheduling

Advanced planning and scheduling system

MRP -> Material Requirements Planning

Material requirements planning for production

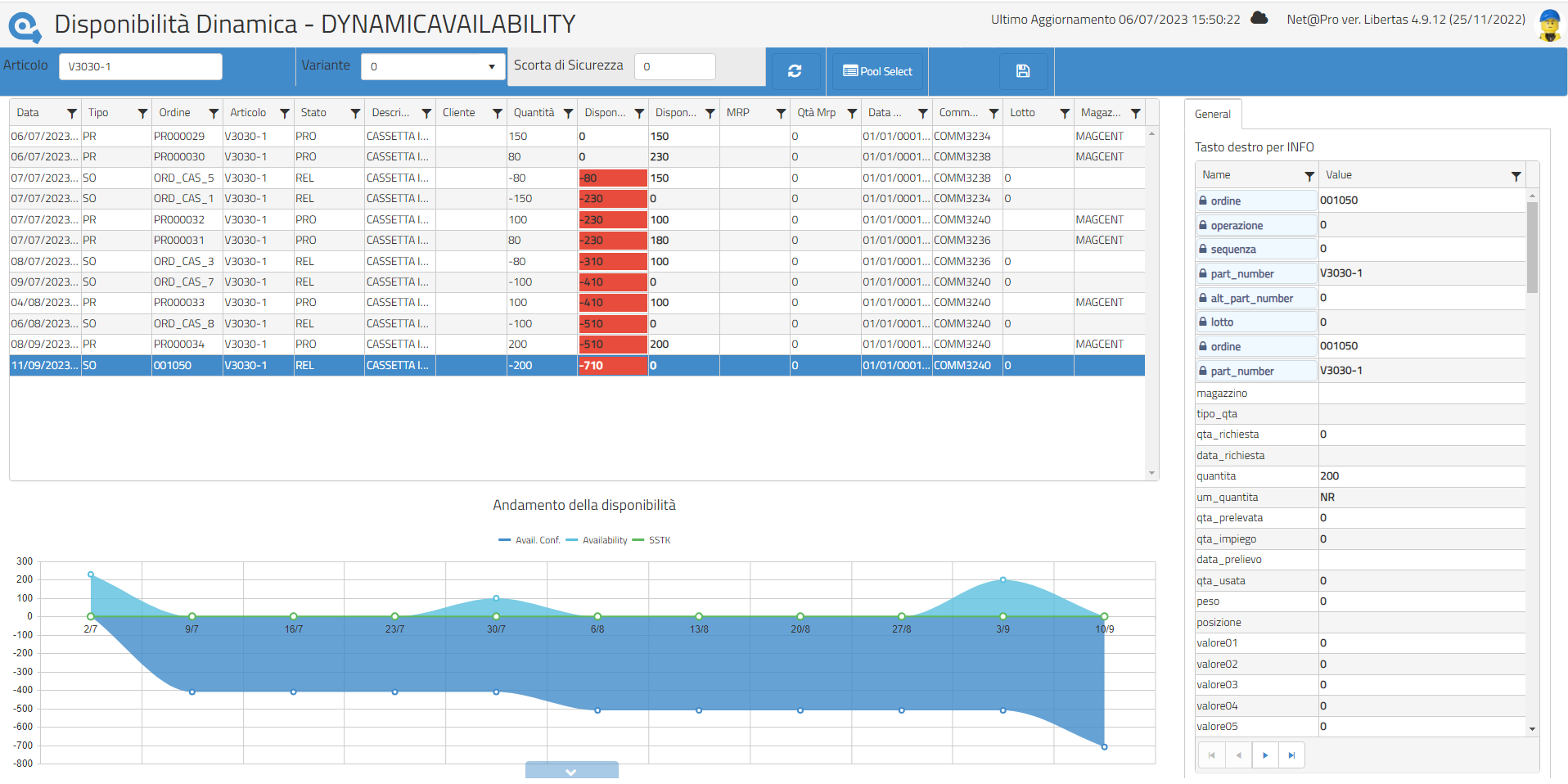

DDMRP -> Demand-driven material requirements planning

Demand-driven material requirements planning method

Production planning and control softwares utilize algorithms that offer support when facing and managing daily production with its urgencies, emergencies and sudden unavailability of materials.

In every company there is a role that must answer the following questions:

- What to produce and purchase?

- How much to produce and purchase?

- When to produce and purchase?

Good planning makes every single production process stable, thanks to an aggregate production

plan that tries to synchronize:

- The arrival of raw materials;

- The production of semi-finished products;

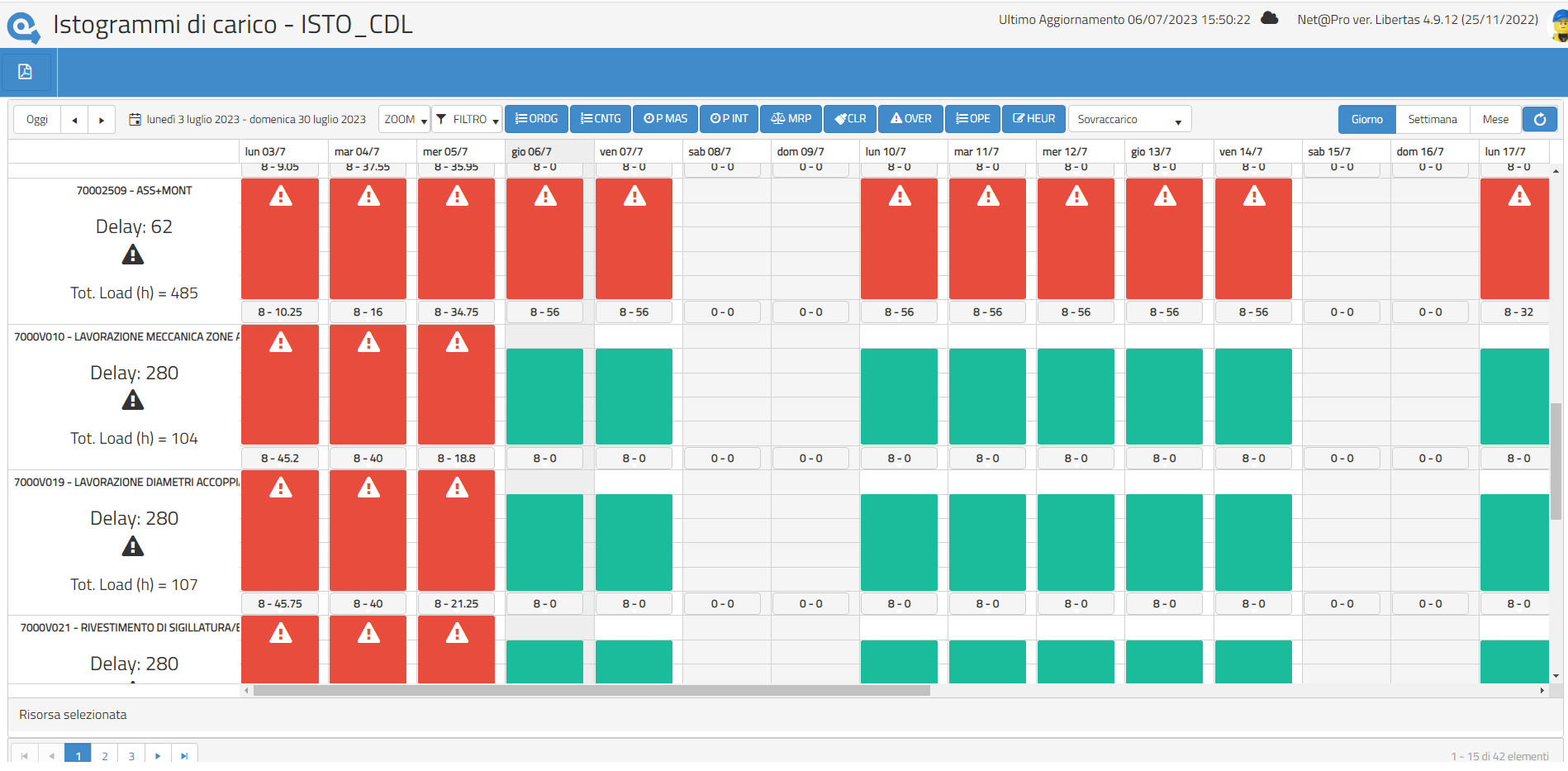

- The availability of machines and equipment;

- Meeting the promised delivery date.

APS allows advanced production planning and scheduling and is designed to extend MRP practices.

MRP is the calculation motor that specifies which materials to order, in which quantities, for when they are needed and when to start the entire process so that the products are ready by the expected completion date.

Traditional MRP is intrinsecally based on the forecast and reasons along the lines of infinite capacity. More specifically:

- Inventory netting: calculates how much must be produced net of inventory. .

- Purchases are determined depending on the moment something is required (Lead time offsetting).

Nowadays, a supply chain is more uncertain and complex, and requires planning abilities that are sensitive to real-time fluctuations of demand. And this is where demand-driven MRP comes into play, representing an evolution compared to the traditional MRP approach, offering greater flexibility and ability to adapt to change in the context of production and demand.

In conclusion

In the presence of a timeline, things that happen today fall under the MES; what happens tomorrow or a week from now is a matter for the scheduler/sequencer (MRP Schedule); whereas what happens a month from now is a task for the MRP planner.

The strength of these systems is that they work together, they integrate and share information to facilitate the job of manufacturing companies, i.e. improving the efficiency of their business

Request information

Our specialized Qualitas team is here to provide expert advice and a free checkup to improve your company's productivity with a NET@PRO MES software demo and a functional analysis of the production flow.

Complete the form or write to ufficiomarketing@qualitas.it or call

+39 0445 641844